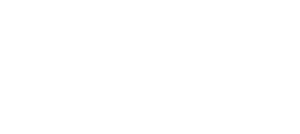

Source: Pinterest

Owning a hyperbaric chamber offers you access to treatments whenever you need them without having to leave your home or pay for each session. This can be especially convenient if you have a chronic condition like arthritis or are recovering from traumatic crash injuries and require frequent sessions to keep inflammation at bay.

Buying a hyperbaric chamber may seem like the only route to such convenience. However, some people enjoy the challenge of a DIY project and may thus choose to build rather than buy a hyperbaric chamber.

But, is building a hyperbaric chamber truly a viable option? How does the process work? Is it a project worth taking on? What are the risks and rewards involved?

Read on as we provide answers to all this and more.

The Design

The design process is a conceptualization phase where you figure out what type of hyperbaric chamber you would like to build. You can make a sketch, assign dimensions, select materials to suit your design, and choose details such as whether you would like a monoplace or multiplace chamber. This would also be the right time to plan how the device will work and the safety measures that you should put in place.

The Components

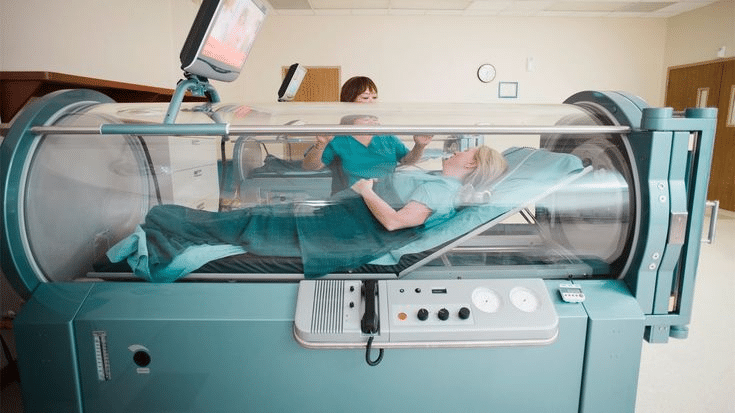

Source: Pexels.com

Building a hyperbaric chamber comes with a very unique shopping list. You will need to find and buy components such as:

- Material to make the frame (e.g steel)

- The shell; this requires airtight walls and a viewing window. Acrylic and polycarbonate are popular choices for this.

- Materials to line the interior appropriately.

- A reliable door system that can safely withstand hyperbaric pressure

- Tubing to connect the chamber to an oxygen source

- Valves to regulate pressure and oxygen levels

- Gauges to monitor the hyperbaric conditions

- Air compressors

- Oxygen concentrators

- A control system to operate the hyperbaric chamber

You can get these items from hyperbaric chamber manufacturers or manufacturers that specialize in making hyperbaric chamber parts. It is crucial to have the right specifications for each component so that they all fit right and can work harmoniously.

The Process

This stage entails putting all the hyperbaric chamber components together to make a functional chamber. It usually requires:

- A deep understanding of hyperbaric chamber design

- Skill in airtight construction techniques

- Knowledge of safety measures and how to ensure your chamber adheres to them

The lack of expertise can lead to rookie mistakes or oversights that can, in the end, be extremely risky for anyone using the chamber or anyone around the chamber. Nevertheless, if you choose to do it, consider consulting an expert or obtaining a detailed manual to guide you through the construction.

Safety Concerns

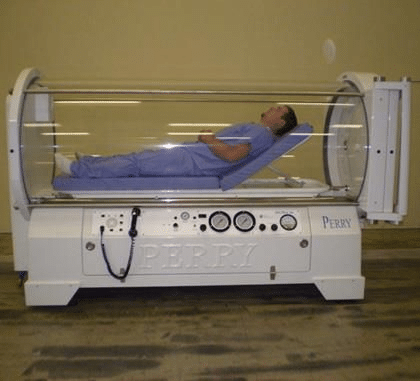

Source:pexels.com

Hyperbaric chambers are generally risky due to the pressure factor and high flow of oxygen. Any mistakes in the construction, running, or operation of a hyperbaric chamber can, therefore, have dire consequences.

For example, if the pressure in a hyperbaric chamber is not well-regulated, it could lead to a collapse of walls, an explosion, barotrauma, and even the death of the person in the chamber. Oxygen leaks, on the other hand, make it very easy for accidental fires to occur because oxygen supports combustion.

Other safety concerns include:

- Improper chamber sealing – if a chamber is not completely air-tight, it suffers air leaks. This negatively impacts the safe pressure balance that you should have in a hyperbaric chamber.

- Inadequate ventilation – ventilation in a hyperbaric chamber entails keeping a consistent flow of air in and out of the space. If the ventilation is not done right, carbon dioxide will likely build up in the chamber and pose a health risk for anyone in the chamber. The heat in the chamber is also bound to become unbearable.

Legal Considerations

In most countries, medical devices must meet strict safety standards and undergo rigorous testing before they can be legally sold or used for therapeutic purposes. Attempting to build a hyperbaric chamber without the required qualifications and licensing, therefore, not only violates the law but also poses significant risks to the user.

You could, however, develop your hyperbaric chamber as a prototype and present it for testing by a regulatory authority. It may take time and attract evaluation fees but it is the only way to end up with a safe, legal DIY hyperbaric chamber.

Buying vs. Building

Considering the complexity, risks, and legal implications, it is prudent to evaluate the advantages and disadvantages of building versus buying a professionally-made hyperbaric chamber.

Building a hyperbaric chamber may appear cost-effective initially, but it often results in hidden expenses. The required materials, specialized tools, and professional guidance can quickly escalate costs. Moreover, the time and effort involved in the construction process can be substantial.

In contrast, purchasing a professionally-made hyperbaric chamber ensures reliability, safety, and compliance with industry standards. These chambers undergo rigorous testing, adhering to quality control measures. Manufacturers provide warranties and customer support, ensuring peace of mind for users.

Building a Hyperbaric Chamber

Pros:

- You may, albeit to a small degree, be able to control your costs and possibly make savings compared to purchasing a pre-made chamber.

- Building your hyperbaric chamber allows you to customize it to suit your needs or preferences.

- Finishing your build offers the satisfaction of a DIY project and personal achievement.

Cons:

- The designing, material sourcing, and building processes are all quite complex and time-consuming. They also require expert knowledge.

- You run a high risk of errors, including structural and functional issues, if you do not have the professional expertise it takes to build a hyperbaric chamber.

- You may experience dire safety hazards if the chamber is not correctly assembled.

- You are bound to be held liable if the hyperbaric chamber malfunctions and causes harm to anyone. Building one may also in itself open you up to legal issues for not complying with medical device regulations.

Buying a Professionally Made Chamber

Pros:

- Professional manufacturers offer safety and quality assurances as well as compliance with hyperbaric device regulations.

- Most brands provide expert guidance and support throughout the purchasing process; you do not have to figure it all out yourself.

- Buying a hyperbaric chamber from a credible manufacturer earns you comprehensive warranties and service agreements.

Cons:

- Buying a hyperbaric chamber gives you little control over costs as the price is already set.

- Not all hyperbaric chamber manufacturers offer customization and most that do provide limited customization options based on pre-existing designs.

Conclusion: To Build or Not to Build

While the idea of building a hyperbaric chamber may seem appealing, it is a venture riddled with lots of risks and challenges. Buying a professionally-made hyperbaric chamber from a certified manufacturer, on the other hand, offers a safer, more reliable solution. It equally guarantees you optimal therapeutic benefits which you may miss out on if you build a low-performing DIY hyperbaric chamber. So, all things considered, buying certainly promises better outcomes than building.